‘Do It Yourself’ electrical work is legally permitted in England and is regularly done as a money saving exercise. But DIY projects can neglect essential safety checks, by relying on a cheap polarity tester to verify if something works, after connecting a live, neutral and earth wire. BS7671 wiring regulations gives numerous tests and checks that should always be carried out to ensure an alteration will be electrically safe to use.

checks, by relying on a cheap polarity tester to verify if something works, after connecting a live, neutral and earth wire. BS7671 wiring regulations gives numerous tests and checks that should always be carried out to ensure an alteration will be electrically safe to use.

Supply Type & Earth Method:

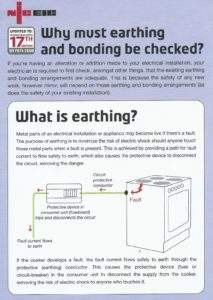

Domestic electrical installations in England rely  upon ‘Earthing & Bonding’ to ensure electrical safety in the event of a fault. Distribution companies often provide an earth termination via their incoming cable, but they are under no obligation to supply an earth. If they have, it can generally be seen connected adjacent to the main supply fuse, such as in this meter cabinet.

upon ‘Earthing & Bonding’ to ensure electrical safety in the event of a fault. Distribution companies often provide an earth termination via their incoming cable, but they are under no obligation to supply an earth. If they have, it can generally be seen connected adjacent to the main supply fuse, such as in this meter cabinet.

When there is no suppliers earth, the property owner has to provide their own termination. Which would typically have an inspection pit and a suitable earth electrode rod sunk into the ground. There would be a removable cover to allow testing and inspection of the earth rod connection;

The importance of satisfactory earth & bonding is emphasised in BS7617 wiring regulations, by the requirement to check the integrity of the incoming supply fuse, meter, supply tails, consumer unit, earthing and bonding before doing any alterations, (Temporary or Permanent), to an installation. Ensuring they are adequate for the circumstances following the proposed alteration. The current 18th edition wiring regulations, which came into effect Jan 2019, states this requirement in regulation 132.16

An awareness of the supply characteristics of an installation has to be known before undertaking alterations, in order to ensure the correct protective devices are selected. Regulation 313.1 identifies that this includes knowledge of the earth method and its value.

Electrical Bonding To Incoming Services:

Earthing and bonding can be considered as important as good foundations for a proposed building extension. If the fundamental safety foundations of an electrical installation are inadequate then in the event of a fault the protective devices may not operate correctly to protect against damage or injury to people, property or livestock.

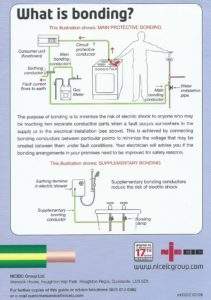

Bonding is additional protective earth connections between electrical earth and incoming metal service pipes. Typically gas & water, but may include other metalwork, possibly oil pipes etc. Regulation 411.3.1.2 gives the requirement for bonding to be installed:

And regulation 544.1.2 states that the connection should be close to the meter or stop tap and before any branches in the pipework:

Visual checks for appropriate earth clamps and conductors can be carried out to verify the presence of bonding to gas & water pipes. There may be a single cable run to a clamp, or there may be a pair of conductors if the bond is looped from both pipes back to electrical earth. Examples of gas and water bonds with both single and looped arrangements;

Preferably the connection should be done with a crimp lug, as this is a more secure joint than inserting the conductor strands under the screw clamp. And if bonding conductors are looped, the connection should be un-broken, to prevent the far end connection being disconnected if the loop point is undone from its earth clamp.

Some Problems Encountered:

Older properties frequently have missing or inadequate safety earth and/or bonding. Also during building alterations it is not uncommon for earth or bonding conductors to become disconnected or damaged. Some examples follow;

Water bond that was hanging loose behind a kitchen unit, probably disconnected due to plumber or kitchen fitters, had to be re-fixed.

A water bond was in the wrong place, (after branches in pipework), it also included a loop via two cables & two clamps. The cables were crimped into a single joint and clamp re-positioned.

A gas bond that has been left lying below the gas meter. Probably disconnected during a previous meter change. (see red arrow pointer bottom centre of image.)

the gas meter. Probably disconnected during a previous meter change. (see red arrow pointer bottom centre of image.)

Sometimes the bonding is in place but would benefit from a bit of minor improvement to bring it to full compliance with BS7671.

A gas bond that was in place but did not have the durable warning sign “Safety Electrical Connection – Do Not Remove” fixed at or near the connection required by regulation 514.13.1.

Checks & Tests Following Alterations:

Before the power is re-energised onto an amended circuit the continuity of the protective conductors should be verified as per regulation 643.2.1;

And regulation 643.7.3 requires that the maximum earth loop impedance value should be measured or calculated to verify the alterations comply with BS7671;

All electrical work should be tested and the results documented on an appropriate electrical certificate. Regulation 134.2.1 confirms this requirement applies to additions and alterations as well as new work.

The prime consideration when designing any electrical alteration is to ensure the amended circuit will “Fail-Safe”, not just that an accessory works when you switch the power on. (A car with faulty breaks, airbags & seatbelts, may appear to work and could be driven for many miles. But when needed to stop and protect you in an emergency could be fatal.)

If you have any doubts about verifying the integrity of your installation’s supply, fuse-box, earthing or bonding it may be sensible to seek professional help, from a competent electrician who has access to appropriate test equipment.

(For additional clarification about earthing and bonding, the NICEIC produced some leaflets giving brief explanations of concepts and their safety implications. see below):

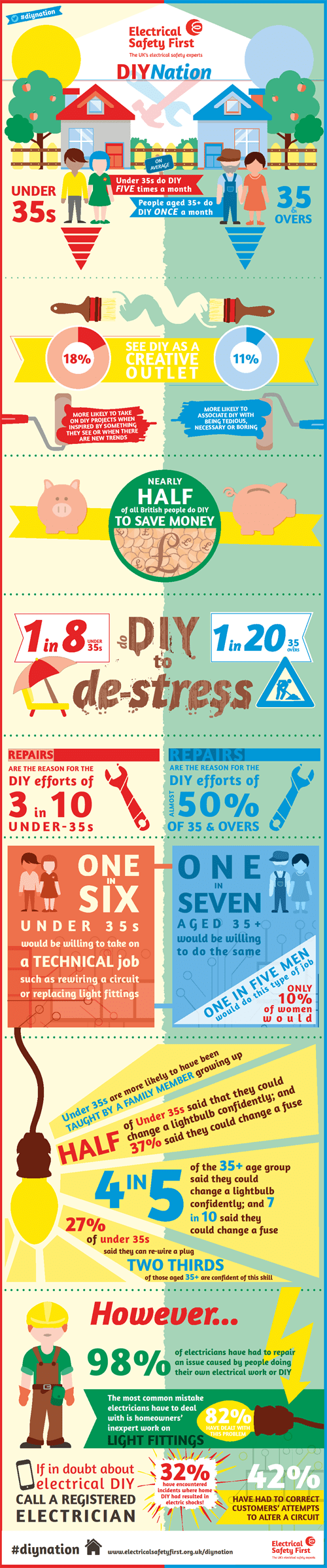

The Electrical Safety Council’s site has numerous articles to help homeowners, including this statistical graphic about DIY work;

From Electrical Safety Council Website

page end -{20Sept20}-