- Electric current can kill a healthy adult in less than a second. It cannot be seen, smelt or heard, therefore it is always dangerous.

- BS7671 wiring regulations, requires circuits to be designed, installed & tested, so that they “fail-safe” in the event of a faulty, by disconnecting the power fast enough to avoid endangering people, property or livestock.

- Also electrical installations can deteriorate with age and usage, so routine checks and tests should carried out at periodic intervals.

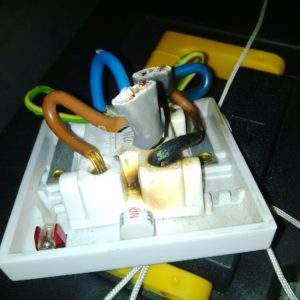

Heat:

Electricity always generates heat in circuit cables. Larger currents, (higher power items), creates more heat. Cables must be capable of carrying the expected amount of current without overheating, potentially damaging their insulation, or starting a fire. Loose termination joints in accessories are another cause of overheating in a cables.

Two shower switches where excess heat due to poor termination has caused melting of insulation.

Shock:

In the event of a fault exposed conductive, (metal), parts could become live creating a risk of electric shock. To prevent shock, all exposed conductive parts must be connected back to electrical earth. Some appliances or accessories are ‘Double insulated’ or ‘ClassII’ which do not require an earth connection. These have the double insulation ‘square symbol’ printed on them.  However the earth wires in the cables must still be correctly terminated and never cut off, to ensure earth continuity to any accessories further along the circuit. When doing alterations or additions to a circuit, earth continuity is an essential test that should be verified before reconnecting the power to the circuit.

However the earth wires in the cables must still be correctly terminated and never cut off, to ensure earth continuity to any accessories further along the circuit. When doing alterations or additions to a circuit, earth continuity is an essential test that should be verified before reconnecting the power to the circuit.

Before the mid 1960’s earth conductors were not required on lighting circuits. If your property has old wiring without an earth conductor then decorative metal accessories requiring an earth must not be fitted to the circuit.

Metal decorative switch with intact old rubber cables but no earth. & Plastic ClassII switch with PVC twin cable without earth.

Old wiring and cable deterioration:

PVC cables, which became common from the 1960’s onward, can have lifespans exceeding 70+ years. But older properties may still be using earlier cables types such as; Tough Rubber-Sheathed, or Lead Sheathed cables from pre-1948. In most TRS or lead cable is beyond its reasonably expected safe working life. But its precise condition will depend upon the amount of loading, heat, exposure to UV light, physical movement etc. the cable has been subject to.

It is not uncommon for the insulation on older cables to become brittle, inflexible and prone to crumble if attempting to replace accessories. If you think your wiring may be outdated non-PVC wiring it is best to get it tested ASAP to verify its condition and leave undisturbed until it is either replaced or verified as still functionally safe. (some rubber cables can still be electrically intact).

Old perished rubber wiring at sockets, light switch and light fitting. (These were on installations still being used with obvious dangers visible.)

Faulty Components:

In addition to wiring problems, accessories can fail due to natural wear, or defective components used in their construction. If an accessory fails, you want to be assured the supply circuit is correctly designed with cable and fusing protection to disconnect the power before a situation becomes serious.

An overheated dimmer switch, showing melting and burning.

External Influences:

Outdoor wiring and accessories can deteriorate due to effects of weather, damp, cold, UV sunlight etc. But internal fittings can also deteriorate due to damp ingress or insects. Corrosion can cause faults on electrical connections, fixing screws, cases and covers etc. Electrical burning smells, crackling or buzzing sounds may indicate a faulty accessory. Without routine inspection of the circuits and accessories, deterioration can go unnoticed leaving increased dangers in the event of a fault. The types of hazards highlighted here are some of the reasons why wiring regulations recommend domestic installations are inspected and tested every 10 years or change of occupancy.

An socket outlet fitted to an external wall with damp problems and a few visits by spiders.

The old traditional Wylex fuse box, with wire fuses:

Historically many properties had a Wylex fuse-box, with fuses that you had to physically replace a wire in the carrier if a fuse blew. Some people claim these are ‘illegal’, ‘dangerous’, or ‘non compliant with wiring regulations’. Which are all factually incorrect.

Three traditional domestic Wylex boxes, 3-way, 4-way, 6-way.

As BS7671 wiring regulations is non-statutory it is not possible for a fuse box to be illegal in relation to the wiring regulations.

Any fuse box is dangerous if the protective devices, cable sizes and loads supplied are not correctly matched. If it was correctly designed, installed and tested, a Wylex box will not be dangerous assuming it is physically and structurally sound.

The type of wire fuses used in these boxes are called BS3036. They are still an acceptable means of overload protection as listed in the current wiring regulations, table 41.2 page 61. So they cannot be a non-compliant option of protective device.

Additional external RCD shock protection would probably be needed to make such an installation safer and fully compliant in the event of any addition or alteration work being carried out.

In the event of a fuse blowing, they are less convenient and have the danger of someone putting the wrong gauge of fuse wire into the holder. In which case the installation would become unsafe and a potential danger. (With a modern box the fuses are a simple trip switch operation, to reset the power once the fault has been cleared.)

An analogy could be a comparison of modern cars -vs- old classic car. Both can be legally and safely driven on the public highway.

But in the event of poor driving conditions or an accident, a modern car fitted with airbags, ABS breaking, seatbelts, fog lights, crumple zones etc.. would be a safer option than an old car without any of these modern safety features.

An old Wylex wired fuse box is not unsafe, BUT it is not AS safe or convenient as a modern consumer unit.

HOWEVER.. just as older cars need a bit more TLC and servicing to keep them running smoothly an older electrical installation needs to be monitored adequately to maintain a safe and functioning supply to all of your appliances.

If your property has an old Wylex fuse box, it is probable that wiring is also quite old. If you have had no formal inspection within the past 10 years it would be wise to get it checked and tested to make sure there are no hidden dangers with deteriorating circuit wiring.

Some applications of using electricity can introduce increased risk of shock or overload:

Outdoor power (Sheds, garages and workshop): The risks and dangers of outdoor electricity and external wiring are numerous. Great care should be taken when obtaining power for use in outbuildings. Long trailing leads across gardens should be avoided for any semi permanent arrangement.

Extension leads: Due to the increased risk of overload and damage to flexible cables, extension leads should kept as temporary use only and not used as a permanent source of power. They should never be used still coiled up on a drum reel. Higher power appliances, consuming more than 10 amps each, Cooking, Heating, Washing etc. should be plugged directly into a wall socket, not a multi block extension reel.

Hand tools: Portable hand tools must be kept in good working order, never use equipment with broken or damaged cases, covers, flexes, plug tops etc.

DIY work: DIY work has dangers from poor workmanship, lack of correct testing, accidental damage to electrical fittings, or drilling walls where live cables may be run etc.

Electricity and Water: Environments where splashes or washing down occur should have appropriately rated electrical accessories to prevent water ingress and damage.

Lighting: Always use the correct power rating of lamp in a light fitting. Keep lights mounted a suitable distance from walls, curtains or any other surfaces susceptible to damage by the heat from the lamp.

General wear and tear: Concealed wiring can be deteriorating or damaged unseen over a long period of time. Without routine inspection and testing it is impossible to be sure that your installation has not deteriorated to an unsafe condition. BS7671 wiring regulations recommends formal inspection and testing once every 10 years or change of occupancy for domestic dwelling. (every 5 years for rented accommodation).

If you have any doubts about your appliances or wiring, or if you have experienced any strange electrical smells, crackling or sparking noises, or RCD’s randomly tripping then arrange a formal inspection as soon as possible.

-{page end 20Sept20}-